By this point loyal readers will know that coopers are the craftsmen who carefully construct the wooden wine barrels we call casks. It’s a masterful trade carried on by years of tradition, yet today the craft is dying out to newer technologies and fewer coopers to pass along the culture. But that’s beside the point, the history of cooperage was the topic of last week’s blog. This week we want to know what is so special about the casks themselves? This is one of many questions our student documentarians set out to research at the onset of pre-production.

I’ve got a small favor to ask… let’s talk casks!

As the central product of the cooper, casks have a robust history of function across history and several continents. Used in wartime explosives by the Celts and beer breweries by the Egyptians, the function of a cask in modern Spanish wineries has to do with a matter of chemistry, aroma, and flavor.

As the central product of the cooper, casks have a robust history of function across history and several continents. Used in wartime explosives by the Celts and beer breweries by the Egyptians, the function of a cask in modern Spanish wineries has to do with a matter of chemistry, aroma, and flavor.

There are three main oak types that traditional wooden casks are commonly made from: French, American or European.

The reason oak is used for barrel-making is because of the many unique properties it has pertaining to the development of wine. First, oak is very porous, meaning that the wine can breathe allowing for micro-oxygenation to occur. Second, oak contains many unique flavor compounds that are infused with the wine. These compounds add a range of flavors, from caramel and vanilla to spices and coconut. Third, oak’s tannin structure and texture interact with the wine to create a softened, refined, and smooth flavor. Finally, oak barrels have beneficial microorganisms that help in the development of the wine by adding even more complex and unique characteristics to the final product.

Casks are frequently toasted on the inside, prior to wine storage, as a means of bringing out the natural flavors of the oak. Toasting caramelizes the natural sugars in the wood, and different degrees of toasting produce different results. Light toasting, occurring at a low temperature, creates a soft, delicate flavor profile. It allows the freshness of the wine fruit to shine through and activate the tannins (chemical compounds from the barrel oak and skin, stems, and seeds of the wine fruit) giving them greater potency after aging. Medium toasting, occurring over a longer period of time, provides greater notes of oak, vanilla, and caramel, and pairs greatly with toasted spices, honey, or chocolate. Heavy toasting occurs quickly and produces bolder accents of vanilla, espresso, butterscotch and smoke. It often complements bold reds and fortified wines (wine containing distilled spirits) like port, sherry, brandy or cognac.

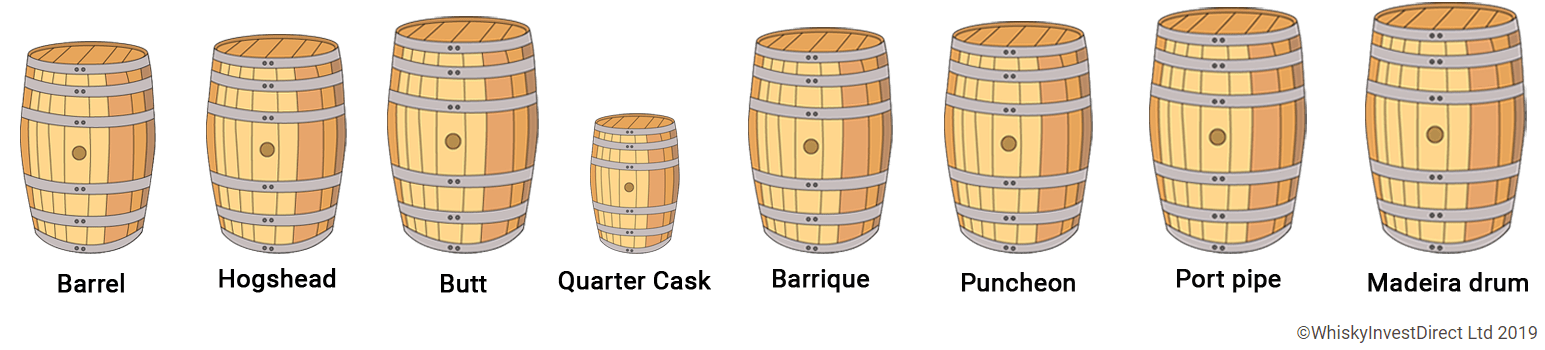

Casks also come in various sizes, which are standardized under different nicknames, like hogshead or puncheon. Size can also indicate what type of oak is used for the staves, as well as affect the quality of the wine and how long it will take to mature.

So there you have it!

Cask preparation makes a world of difference! Essential to the flavor profiles, texture and overall quality of the wine itself, it is pertinent that both the cooper and the winemaker consider what kind of oak, toasting, and size of cask they need to endow their products with the most promising affect. Cooperages globally are renown for their distinct styles of cask-preparation and the desirable effects their casks have on the tone of the wine.

Cask preparation makes a world of difference! Essential to the flavor profiles, texture and overall quality of the wine itself, it is pertinent that both the cooper and the winemaker consider what kind of oak, toasting, and size of cask they need to endow their products with the most promising affect. Cooperages globally are renown for their distinct styles of cask-preparation and the desirable effects their casks have on the tone of the wine.

Our team hits Córdoba running in less than five weeks to investigate these casks and their makers in-person! Be sure to follow along on our socials to track our progress.